New B2B commerce study

Download nowA digital twin that ensures uniform incineration conditions

Data-driven optimization of hazardous waste utilization

Sewage sludge and hazardous waste are used to generate electricity and heat for hundreds of thousands of Viennese households.

Whether waste oil or shredded barrels: the fire keeps burning.

A turbine converts the energy released when the hazardous waste is burned into electricity. Wien Energie uses the heat directly for the city’s heat supply.

The challenge

Low-residue incineration despite variable waste composition

Regardless of whether hospital waste, solvent mixtures, waste oil or something else is being fed into the incinerator, the incineration process must continue at several hundred degrees Celsius. Not so easy, because the delivered hazardous waste cannot be checked beforehand for its exact composition and thus for its thermal and calorific material properties.

In the two cylindrical rotary kilns, the waste is rotated slowly at a slight gradient to ensure that the different types of waste are incinerated as evenly as possible and with as few pollutants as possible.

The solution

Sensor data optimize process control and operating efficiency

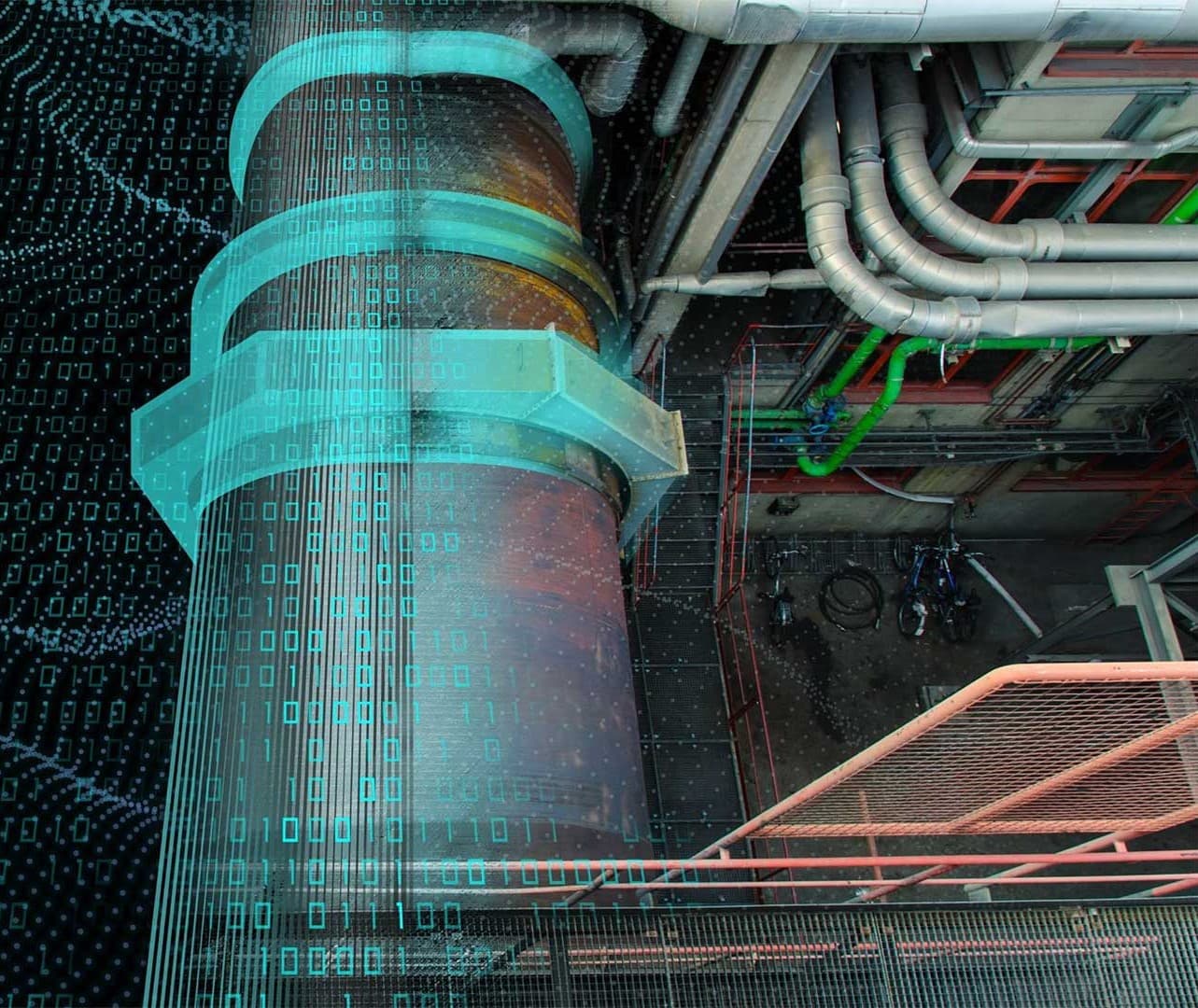

A digital image of this rotary kiln was designed to simulate the incineration process in a dynamic-physical model.

We use the delivery data and the sensor data measured in the real world as input for the dynamic-physical model. We match the measured sensor data with the simulated sensor data. This allows us to characterize and systematize the fed waste compositions and their incineration behavior. Big data and machine learning algorithms help to build a database and gain insights into the delivered waste to improve process control and operational efficiency.

The digital twin creates enormous optimization potential. With permanent monitoring, deviations such as faulty measurements and sensors can be detected at an early stage. Temperature peaks sometimes lead to failures. Because these become less frequent thanks to seamless monitoring, downtimes could be reduced by up to 25%. This would result in around 500 tons less CO2 emissions per year due to the lower fossil fuel oil consumption in the heating process after shutdowns.

Our project partners

Wien Energie

Wien Energie supplies energy to two million people and 230,000 commercial and industrial facilities. Electricity and heat production comes from renewable energy sources such as solar, wind and hydropower as well as biomass, waste recycling and combined heat anie zd power. With a turnover of 1,948.1 million euros and 2,167 employees (2020), Wien Energie is one of the 30 companies with the highest turnover in Austria.

Vienna University of Technology

TU Vienna has been an institution for research and education for more than 200 years. In the Thermal Twin 4.0 project, a team of experts from the Institute of Process Engineering, Environmental Engineering and Technical Biosciences is developing the general rough classification of input streams in terms of thermal properties and the partial models of the combustion processes.

Enrag

Enrag provides customized digital twin software development for engineering applications. In this project, Enrag integrates all submodels to create an equation-based digital twin of the entire plant.