Digitalization protects the logistics sector from analog chaos

The logistics sector in the DACH region is characterized by a very fragmented cross-section of companies. Both the size of companies – ranging from global mega-corporations such as UPS, DHL, Kühne + Nagel & Co. to medium-sized freight forwarders and service providers such as Hermes or LKW WALTER, not forgetting small- and micro-enterprises – and the lines of business often diverge considerably. Whether it’s warehouse logistics, supply chain, or transport logistics, using their own vehicles or only acting in the role of control and fulfillment provider, the need to optimize their processes, eliminate interfaces, and drive digital networking unites all these companies.

Status digitalization – the course has been set, the work is still to be done

Even though warehouse and transport logistics are directly connected, the measures adopted in terms of digitizing and optimizing the processing logic are often very specific in the different areas. Optimized warehouse logistics at a particular site and intelligent route management on the motorway are worlds apart in terms of disciplines. Yet they cannot be separated for digitalization, in particular, as there is often a lot of time and efficiency lost at precisely these interfaces. This is because warehouse logistics and transport logistics are not harmonized, as confirmed in a study conducted by the Federal Association for Logistics (BVL) and T-Systems.

These problems have been known in logistics for some time. Moreover, the money, willingness, and inspiration to tackle them has generally been lacking. However, many logisticians have since identified the opportunities and necessities presented by digitalization and can now build on the best practices developed by pioneers in their sector.

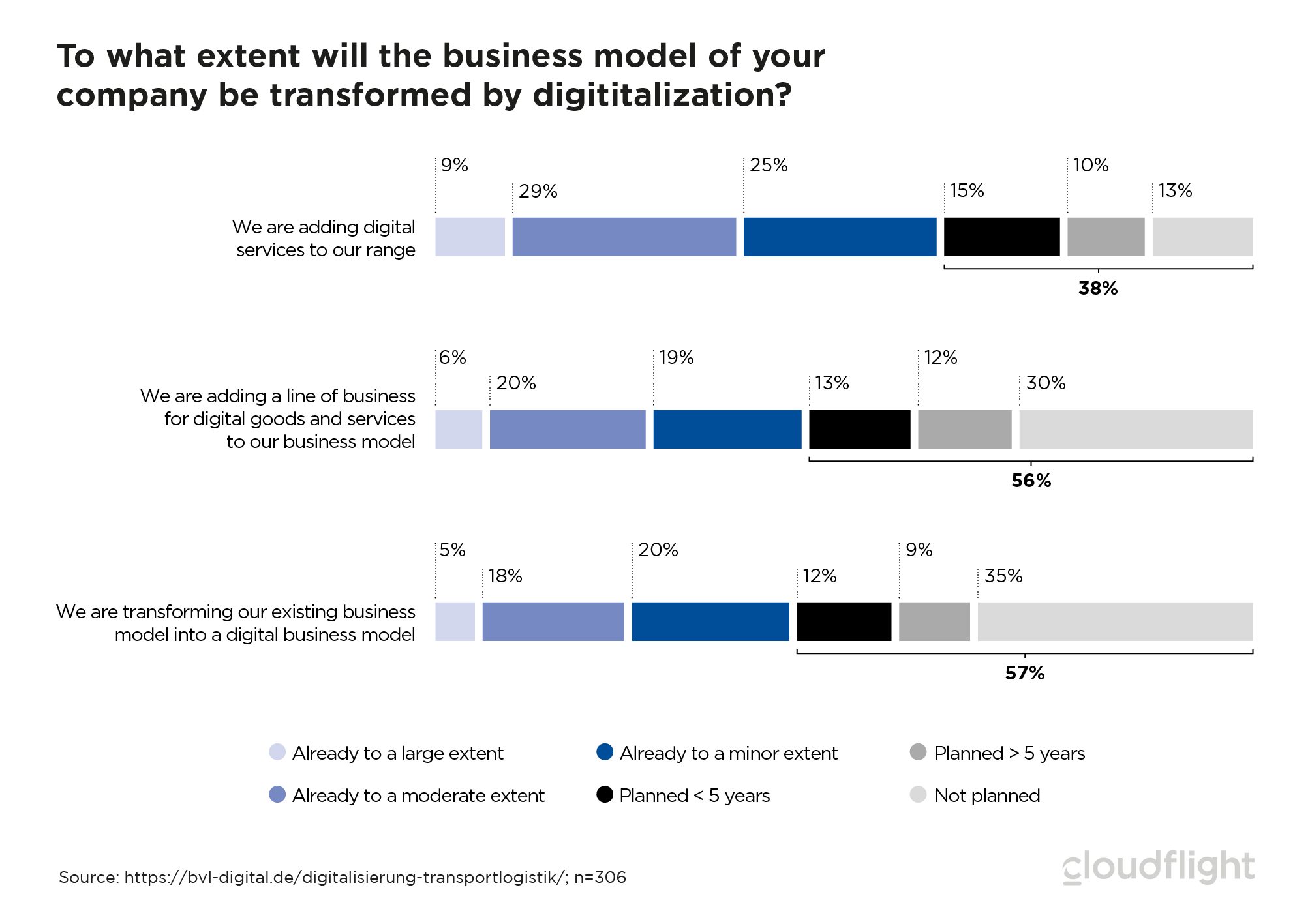

The level at which digital technologies are implemented into process and business model development remains very low and is limited to just a small number of companies that have been bold enough to take the first step. Only less than 10 percent of all companies can report the progress of any note in the implementation of digital services and new business models or lines of business. The remaining companies are still working on making a breakthrough or are only planning on taking this leap sometime in the future. In terms of business model transformation and adding new lines of business to the core business, one-third of logisticians remain skeptical of being able to implement these steps successfully in the future.

However, for digitalization to be a success in logistics, where goods pass through many hands from production sites to end consumers, standardization must be driven – in the truest sense of the word – across sectors. Only then – when the exchange of data, the associated integration and networking, and the subsequent seamless process flow can be ensured – can all companies claim to have achieved a degree of success in this transformation.

Drivers of digitalization in logistics – environment, consumers, and employees in focus

The motivation for logisticians could not be higher. At nearly full capacity and with ever-increasing transport volumes on almost all routes, there are numerous drivers where digitalization appears to be the saviour:

- Sustainability – Emission-free or at minimum CO2-neutral transportation of goods will soon become a mandatory exercise for all logisticians. Empty runs, detours, or old drive concepts must become a thing of the past. The networking of trucks and the electric drive will have a significant impact here.

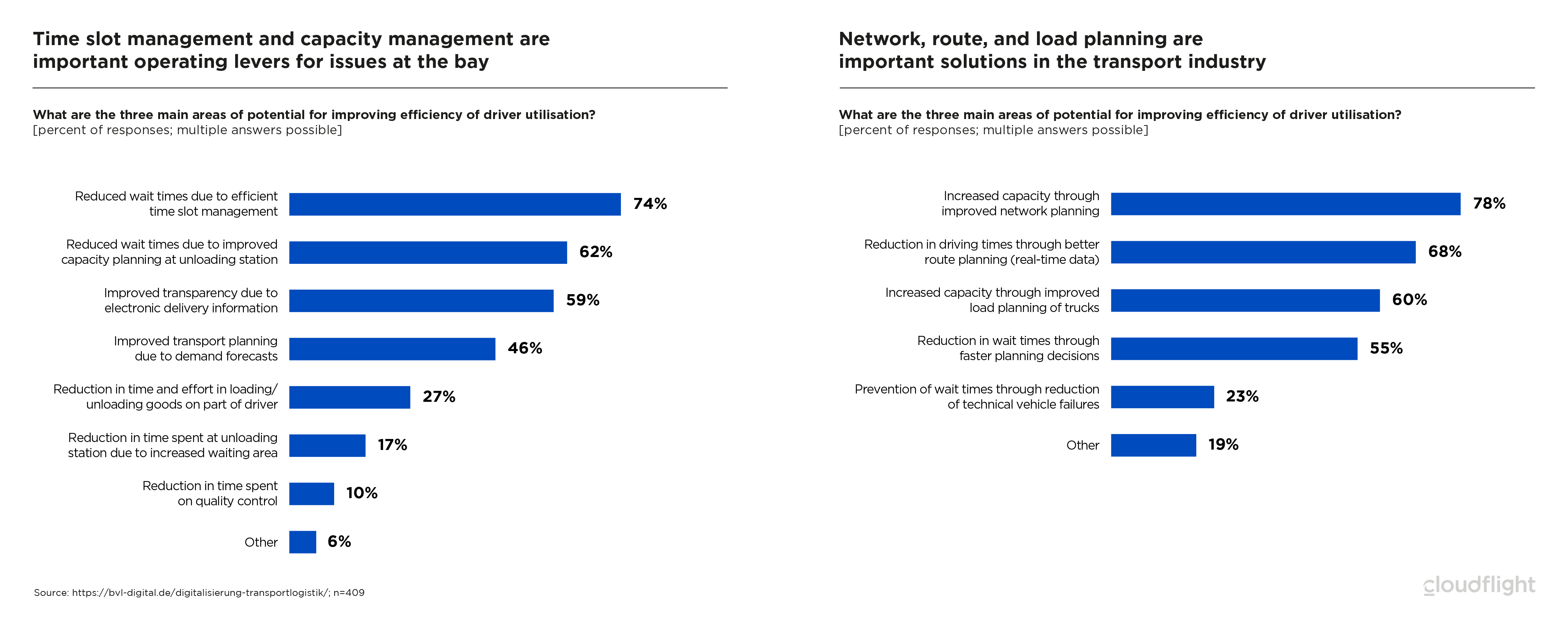

- Efficiency – There are still long wait times at logisticians’ interfaces, e.g. loading bays. Even the optimization of routes, merging of trips, and the associated increase in transport volumes per trip are challenges that can be tackled almost exclusively with the support of data and complex algorithms that identify such inefficiencies and provide recommendations to overcome these issues.

- Networking – Cooperation between many logisticians and participants along the supply chain is often analog and rarely standardized. If this cooperation could be more strongly driven by uniform digital standards and maybe if central control tools accessible to all participants could be used, then significant benefits could be achieved here.

- Online trade – If there is one winner in the current overall business and economic situation, then it is most probably online trade. Volumes in e-commerce have again increased significantly both in the case of established companies presenting offers and new businesses that have had to move online out of necessity. Amazon has evolved into the logistician for the final stretch over recent months and shown that same-day-delivery is possible by networking and standardizing the supply chain – if you can beat it, join it!

- Corona –Even if it’s no longer big news to say that the coronavirus has changed the economy and society, the pandemic is still a driver for the digitalization of logistics. Such changes include, for example, the introduction of social distancing concepts and automation measures or contactless picking in warehouses, to satisfy the regulatory obligations on prevention. The same is true for the interfaces between warehouse and transport logistics.

- New work – Many professions in logistics, in particular for long-distance lorry drivers, are still a lifelong dream. Nevertheless, new work models and trends from the new work movement also have an impact on the people involved. The balance between career and family, the use of modern technologies for everyday work, and the simplification of processes for each individual through access to smartphones and apps instead of pen and paper are legitimate requirements that need to be fulfilled.

- Safety – This also covers the safety of all participants in particular. Especially for professional drivers, breaks, safety concepts, and assistance systems can be a potential lifesaver, which are only made possible through data and digital services.

Fields of action & use cases of digitalization

These opportunities allow managers at logistics companies to potentially reduce wait times for their drivers, maximize transparency of processes, and further optimize route planning.

- Installation & update of hardware and software – Many logisticians first need to create the basis for digitalization. End devices and sensors within warehouses and trucks are just as necessary as setting up a software landscape with all the relevant applications required to enable interaction. This enables companies in logistics or ideally as a consortium to contribute to providing simple applications for employees that digitally map analog processes so that paper usage is reduced and workflows are simplified and can run error-free.

- Digital infrastructure – An adequate digital infrastructure is required in order to exchange and evaluate a high volume of data and also provide every employee with the software no matter the location. Cloud computing and hybrid cloud landscapes are becoming the method of choice for operating applications and IoT platforms in a quick, flexible, and highly efficient manner.

- E-commerce – On one hand, e-commerce is the biggest driver for logistics in terms of increasing order volumes. At the same time, it also represents an opportunity for logisticians themselves to move orders online and therefore have all the information stored directly in a central location and integrated for partner companies and customers. With the creation of an e-commerce platform as logisticians, especially in B2B business, companies get the optimum point of entry ensuring more transparency and optimized route and price planning.

- Data-based business models – Digital platforms and services like Track & Trace have been part of logistics for some time now. However, new potential can be unearthed beyond this with the networking and use of data. The knowledge that can be gleaned from the data generated by networking trucks and freight is a valuable commodity for many companies. Similarly, the above-mentioned process benefits can be realized through networking with other logisticians. When it comes to data, it is therefore a case of give and take for logisticians!

- Artificial intelligence – Being able to generate information from data and make it available in digital form is already a quantum leap. Furthermore, with the help of artificial intelligence, it can also be used to identify patterns and opportunities for improvement in the process, continuously improve process optimization, and take actions either in an automated manner or in the form of recommendations using the digital assistant. AI is set to be a game-changer in all areas of logistics.

The Cloudflight vision – digital assistance as Transport Manager 2.0

The following question needs to be addressed: How far down the digital road is logistics ultimately going to go? Some projects, for example, the telematics & logistics platform RIO, which MAN, among others, is involved in, or TrailerConnect from Schmitz Cargobull, show that the major truck manufacturers, in particular, are also focusing heavily on digital value-added services in addition to the development of their tractors and trailers. Such services are available to companies and ensure greater transparency and improved processes.

Cloudflight, too, is working closely with companies from warehouse and transport logistics and also wants to develop them into drivers of digitalization. Here, real-time data for trucks/trailers play an important role.

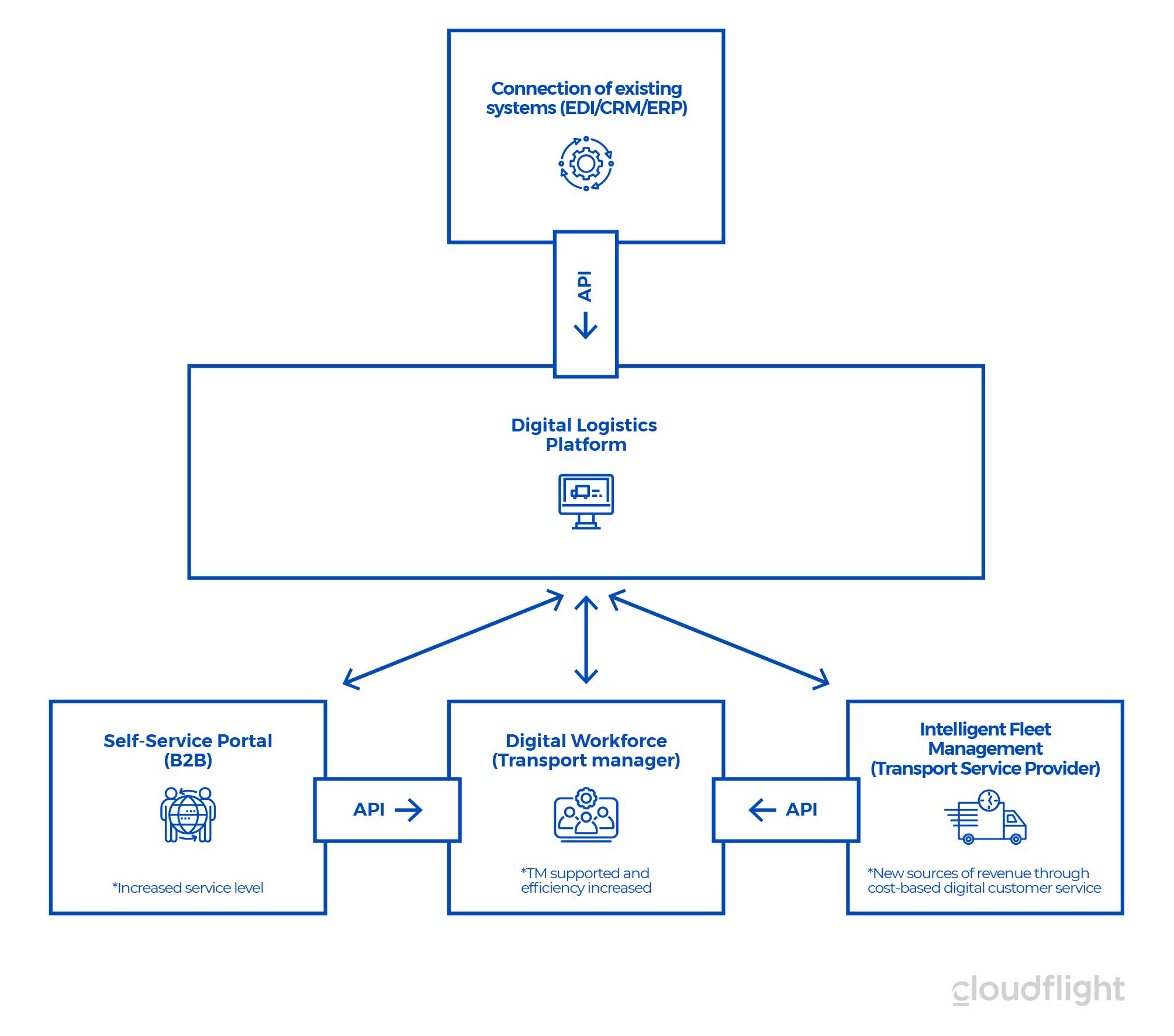

An integrated digital transport logistics platform could, for example, offer a significant advantage to transport managers who are responsible for organizing and planning routes and shipments. Connected to the telematics systems of the manufacturers, the internal back-end systems, the order and service portals, as well as the intelligent fleet and route management could all be brought together on a single platform. Using artificial intelligence, all data, for example, transport volumes, routes, and special requirements for transport could be entered and collected.

Already as things stand today, there are numerous application cases available to the entire logistics sector that can be supported through existing and developed technologies. There is still some work to be done to ensure that warehouse logisticians and transport logisticians can be fully networked from the warehouse stage right up to the final stretch. But it is possible!