New digital business models – when it comes to digitalization, you may have heard these buzzwords more than once. What exactly is meant by them?

One digital business model among many is the Equipment-as-a-Service model, which we explain and present in more detail in this multipart series. In order to make the whole topic a little more tangible, let’s start with the classic mechanical engineering in medium-sized companies as an example.

Current challenges and customer requirements of machine and plant manufacturers

Since the beginning of the pandemic, there has been a high degree of uncertainty in many companies regarding new investment decisions. Nobody knows exactly how the economy will develop – will it recover or will it crash even further?

Only very few CFOs currently release a 6- to 7-digit investment volume. If we speak of “classic” mechanical engineering medium-sized companies, we are usually at least in this price range for a product. There is hardly a special machine available for less budget. As a result, there is a slump in sales, which is of course also passed on to the supplier companies.

What can mechanical engineers do to counteract this? First of all, it is important to take the customer perspective. Their requirements have shifted in recent months and the following points have emerged during this crisis:

Predictable costs – CAPEX vs. OPEX

CFOs love predictable spending and don’t like fluctuations or peaks in the same, to provide good cash flow predictability. Also, it is often easier for department managers to have a monthly lump sum approved by the management than a high one-off investment volume.

Focus on core business and core competence

Companies want to concentrate more on their actual strengths. The procurement and maintenance of bought-in machines, spare parts and consumables are not part of this. In the worst case, these very points distract from the focus.

Guaranteed output quantity

If a company uses a plant, it should at best run faultlessly and have a certain output quantity so that it is profitable. Ideally, the output quantity is guaranteed by the manufacturer and you can rely on the plant one hundred percent.

Risk minimization

The three points mentioned above are all aimed at one main point: risk minimization. In these uncertain times, it is essential for any business to eliminate as many risk factors as possible. As a machine and plant manufacturer, you should have exactly these points in mind in order to remain an important partner for your customers in the future.

It is precisely this knowledge that a manufacturing mechanical engineering company can start with by switching to a “equipment-as-a-service” business model.

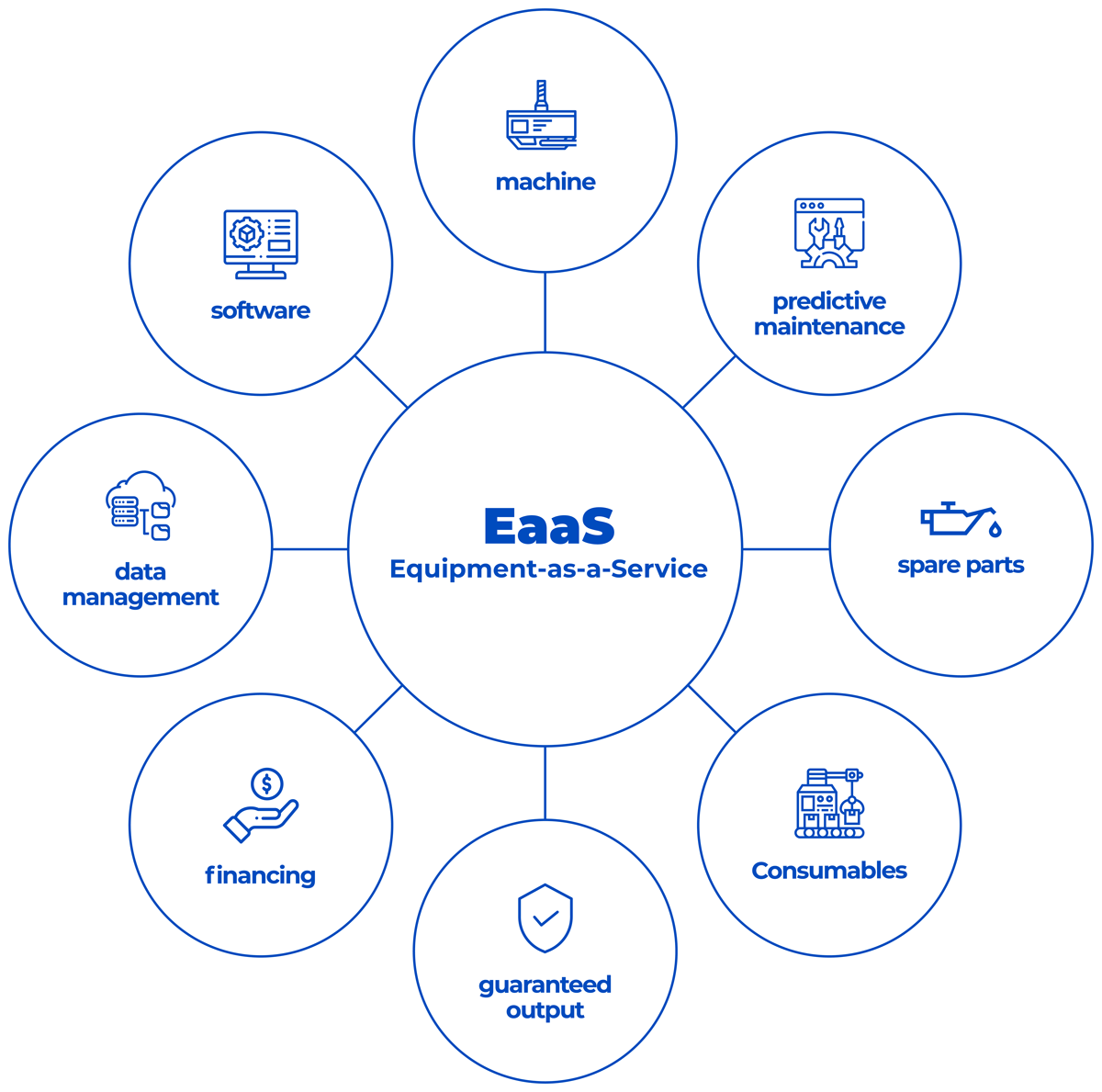

Definition Equipment-as-a-Service (EaaS)

In contrast to the classic sale of a machine, the machine in the EaaS model is provided by the manufacturing company to the user for a fee. The manufacturer is responsible for maintenance, service, consumables and spare parts. Even availability and output can be guaranteed. The user saves the high investment costs and also partly passes on the operational risk to the manufacturing company.

In return, the latter prices the risk as well as the added value for the user into its lump sum. For example, the user fee can be billed monthly or even according to the “pay-per-use model”, i.e. only according to the number of units actually produced. Companies from the plant engineering industry thus generate continuous revenues over the years and not just once when the machine is sold. Well-calculated, significantly more turnover and profit can be generated.

Furthermore, this business model also promotes customer loyalty as a major asset, as regular exchanges take place. This means that the manufacturer is always close to the customer and can better meet their requirements.

Currently emerging technologies such as Artificial Intelligence and the Internet of Things make an EaaS model economically viable. Using predictive models and digital twins, individual machine states can be precisely recorded and predicted.

Does the Equipment-as-a-Service model make sense in times of crisis?

Of course, the resourceful mechanical engineering entrepreneur immediately thinks of the following questions:

- Is an EaaS business model profitable even in times of crisis?

- What happens if there is a production stop with my customers and my pay-per-use model does not generate revenues?

- Should I fundamentally change my business model in these uncertain times?

Let’s look at the facts and compare the “classic” business model with the EaaS approach:

Typically, a mechanical engineering company sells a production line for a one-time price. In the best case, this happened at the end of 2019 or the beginning of 2020. If negotiations were still in progress at that time, the signing of the contract was presumably planned for April, May and June. Presumably at this very time there was a pullback and so far no resumption of talks for the reasons mentioned above. As a result, the expected sales for this year have so far not materialized and a large order volume cannot be expected until at least the end of the year.

Under the Equipment-as-a-Service model with pay-per-use billing, both parties could have agreed in May, as the user bears no risk. If production comes to a standstill, he does not pay anything either. The plant engineering company could now argue that no income is generated here either, despite the delivery of the machine. This is correct, but in fact most companies only stopped production completely for 2-4 weeks, after which production was ramped up again. The manufacturing plant engineering company participated directly in the start of production, since with the pay-per-use model, revenues are generated again directly from the first piece produced.

Thus, the questions mentioned above can be answered with a pro for the EaaS model. Especially in today’s uncertain times, it is extremely important to respond to customer needs and to offer a solution for exactly these big challenges.

So now is the time to think about new business models and implement them so that you can assert yourself on the market in the long term.

In the next part of the series on the Equipment-as-a-Service business model, you will learn more about the advantages and disadvantages and what you should look out for when implementing it.

If you cannot wait until then, please contact us directly for a review and possible realignment of your business model.